Place of Origin:

CHINA

Brand Name:

YOUNGYOU

Certification:

CE

Model Number:

CHLS-238YII

Contact Us

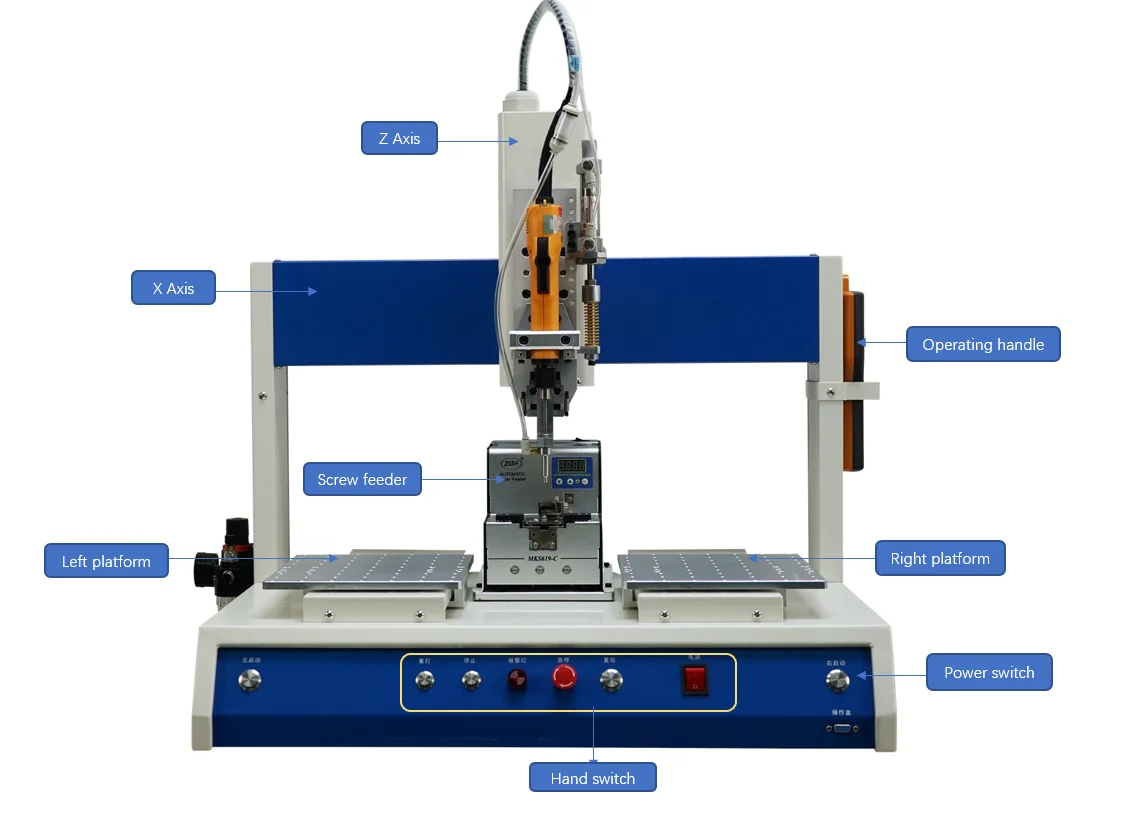

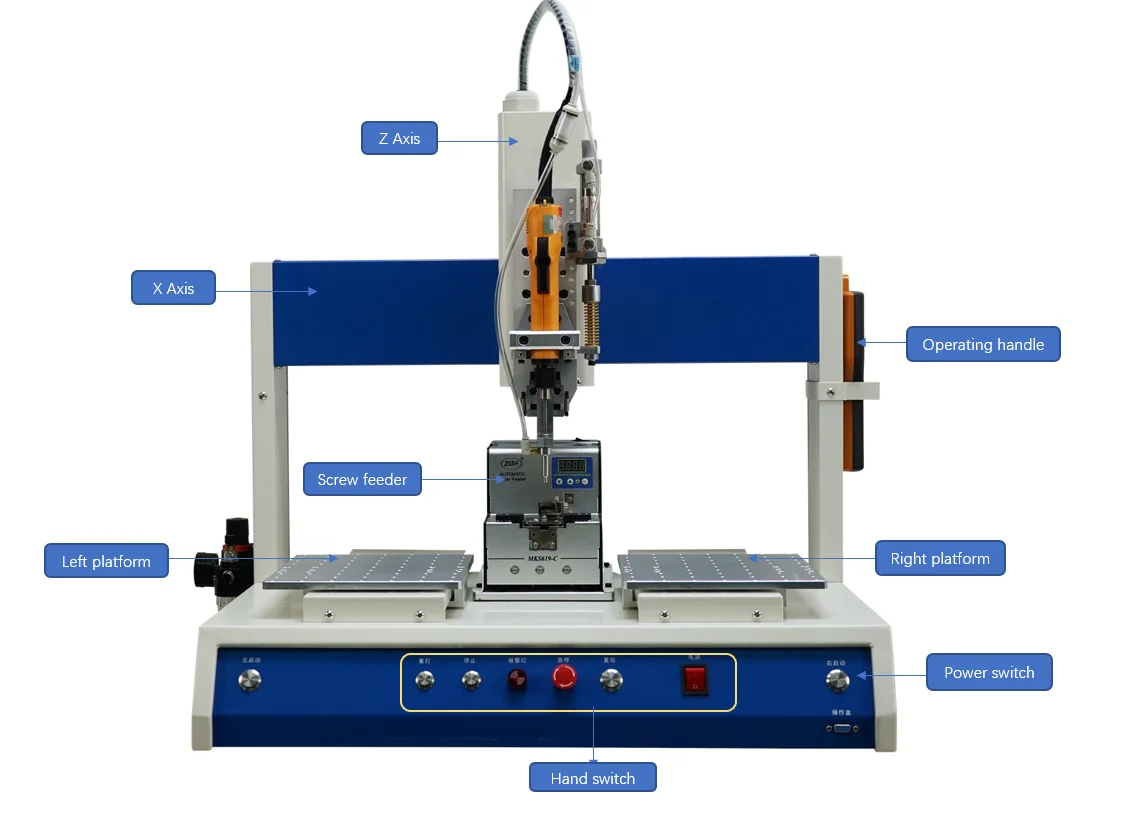

Double platform automatic screwdriver machine.Repetitive accuracy:±0.02mm(X/Y/Z)/Frequency:50HZ

Performance of machine:

1.With intelligent detection function, it can detect leak lock, floating lock, sliding screws, etc.

2.High versatility, the replacement screw delivery module can be adapted to the M1.0-M5 screw lock

3.High flexibility, standard universal clamp for a variety of models of screw locks.

4.Dual platform design, automatic alternate operation without downtime, fast speed and high efficiency

5.2G storage space, which can store thousands of screwdriving programs, each program supports 9999 screwdriving instructions

6.The utility model adopts the vacuum suction screw method, has good versatility, overcomes the feature that the wind blow screw can not send the length to diameter ratio of 1.2, and overcomes the characteristics that the magnetic suction screw can not take the stainless steel screw.

7.The display adopts 320*240 high-resolution color screen and full English operation interface, easy to learn and use.

Industry Status

With the development of automation technology, automatic locking screw machines have effectively solved this problem. The automatic locking screw machine establishes a fully automatic conveyor, tightening, and inspection process for screws based on various electric and pneumatic electronic devices. The screw tightening process is simplified based on machine equipment, which has the advantages of high efficiency, high stability, and high quality, achieving high intelligence and unmanned operation for locking operations. It plays a key role in improving enterprise production efficiency and product qualification rate, reducing employee labor intensity and production costs.

About the company

Our guide rail has cooperated with many international well-known robot brands, such as ABB KUKA FANUC Yaskawa UR. The companies involved mainly include palletizing, loading and unloading. The load of the guide rail ranges from 500kg to 5000kg. The length of the guide rail is customized according to the needs of customers. We have made a case that an ABB IRB6700 robot corresponds to 20 CNC machines, and a 50m long guide rail completes the reciprocating motion, loading and unloading of the robot. The number of robots is greatly reduced and the integration cost is saved.

Our company also offers industrial robots at very favorable prices to place orders together at lower prices.

Welcome to Shanghai, China, to investigate our robots and rails!

Company Product Supply

ABB robot

KUKA robot

Yaskawa robot

Fanuc robot

UR robot

Cobot

Guide rail

Cobot made in China

Product specifications

| Model | CHLS-238YII |

| Moving range | 250X*300Y*110Zmm |

| Processing range | 230X*300Y*110Zmm |

| Repetitive accuracy | ±0.02mm(X/Y/Z) |

| Fixture platform | 2 |

| Welding head | 2 |

| Applicable screw | M1.0-M4.0 |

| Screw conveying method | Vacuum suction |

| Driving mode | precision stepping motor+precision lead rail |

| Axes of motion | 6 axes |

| Display mode | LCD |

| Control system | special controller for screwdriver machine |

| Program record capacity | 9999 |

| Programming interface | teaching pandent |

| Air pressure | 4~6kg cm2 |

| Vltage | AC220V |

| Dimensions | 800X500X725mm |

| Weight | 95kg |

Product parameters table

Packaging and Transportation

![]()

![]()

Send your inquiry directly to us